Get the Job Done!

Are you ready to reduce labor needs and make work more efficient?

Let us do the heavy lifting for you!

What makes Toyo Koken's Manipulator different?

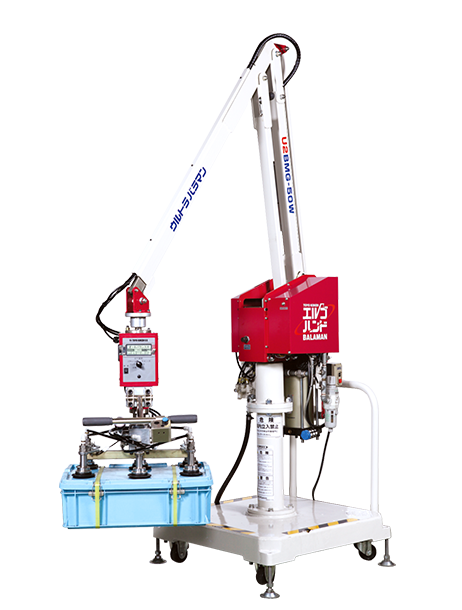

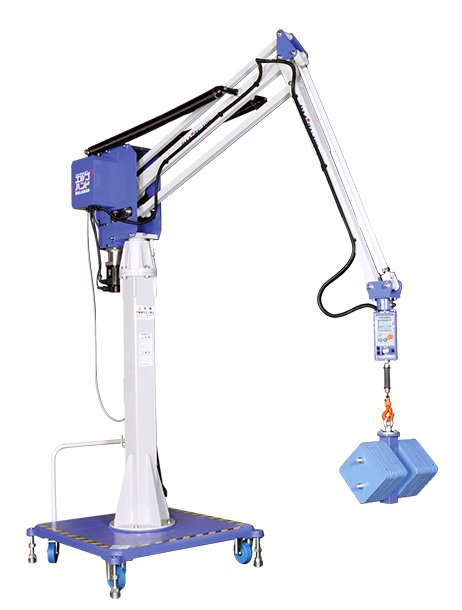

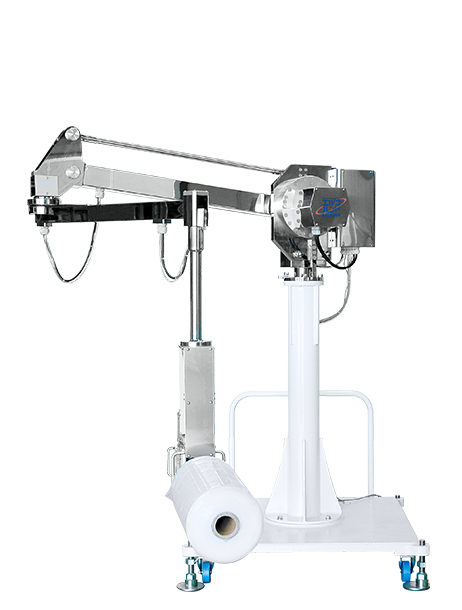

A wide range of models to suit your specific needs.

The pneumatic Balaman, hybrid Balaman and electric Balaman.

Choose from our wide selection of arms to meet your specific needs.

Select your mount--stationary floor mount, mobile floor, and ceiling mount.

Get the right end effector, custom designed for your specific application.

Backed by our expertise gained from our proven track record of over 25,000 units installed

throughout our history, we can design and develop the most ergonomically correct end effector for you.

Too many to choose from?

Let us help you pick the right one. Just tell us:

We will help you pick the optimal main unit, pedestal, end effector and the operation method for your specific application.

Tell us

- What process you want to improve.

- Shape, weight and type of load to be transported.

- Site layout including ceiling height, workpiece travel range, etc.

In Japan, you can try out our manipulators and actually feel the difference.

Customization can be done for special environments such as clean rooms!

For food and other applications that require clean room conditions, our best option is the electric Balaman that uses low-dust parts. The pneumatic Balaman also can be used with a centralized exhaust system.

For explosion-proof requirements such as use in chemical plants, we propose the pneumatic Balaman, which does not use electricity.

Heat-resistant specifications are available for high-temperature areas such as heat treatment processes for metal parts.

By all means, contact us if you are interested.

Balaman

We can help you select the optimal Balaman solution to meet the specific needs of your work conditions and material to be moved.

-

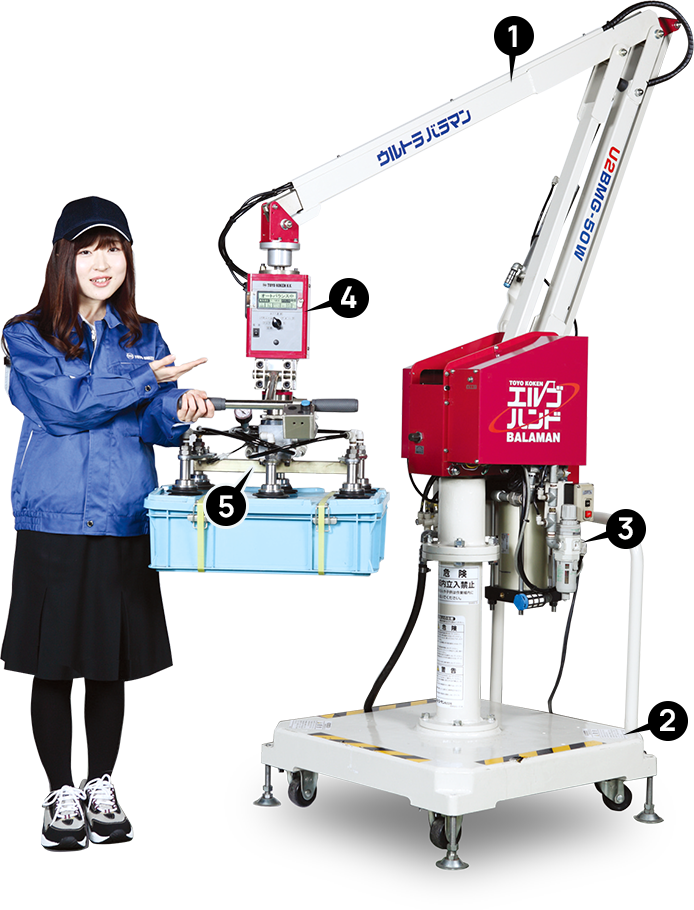

Choice of main body

We select and propose the optimal main body type from a variety of arm types to match the workspace and working condition.

-

Choice of pedestal

We will select the most suitable pedestal according to the layout of the site.

- Floor mount

- Floor mobile

- Ceiling mount

-

Filter regulator

This adjusts the primary air pressure of the Balaman.

Dry air supply is required. -

Relay box with touch panel display

This is onboard the hybrid and electric Balaman.

-

End Effectors

Our end effectors are custom made for the workpiece to be moved and the process.

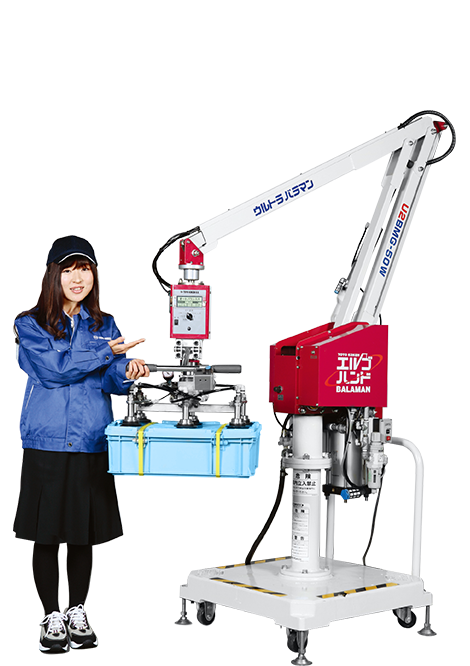

| Model | Hybrid Balaman |

|---|---|

| Main body | U2BMG-50W (Low ceiling model) |

| Pedestal | SNG-50W (Floor mobile) |

| End Effector | Plastic case vacuum |

| Payload | 50kg (including relay box + end effector) Maximum workpiece weight 30kg |

| Operating method | Pick up the workpiece simply by pushing a button to turn on vacuum suction. Easily transport to the desired location. When you’re ready to place it, press the switch again to turn off vacuum suction. |

Information

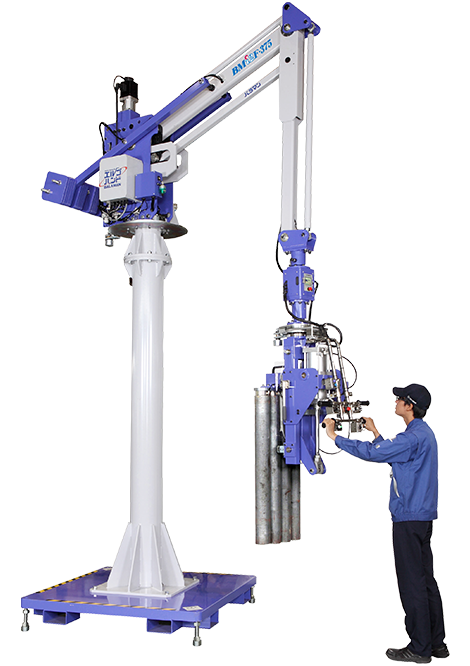

| Payload | We have a variety of Balaman models that can move up to 375kg. |

|---|---|

| Safety | Each model has robust safety features. |

| Operating method | Operating method vary depending on the customization of our product. |

Features

Pneumatic BALAMAN

Just supply compressed air to the Pneumatic Balaman and it’s ready to go!

We have the optimal manipulator to either mass production or high-mix low-volume production environments.

Hybrid BALAMAN

The Pneumatic Balaman comes with electronic controls.

No more tedious switching.

Easy for anyone to operate.

Electric BALAMAN

Balancing function is available even with electrical drive.

A revolutionary manipulator that lets you do more!

What are your challenges?

Do you need to save labor and improve working conditions?

We have to move gallon bottles that weigh 12kg per gallon.

Even holding one is heavy and difficult, but moving them one at a time is very inefficient.

We need a better, more efficient way!

This is the kind of process where Balaman makes it easy.

We design the end effector specifically for such an application, so one to 4 gallon bottles can be transferred at once.

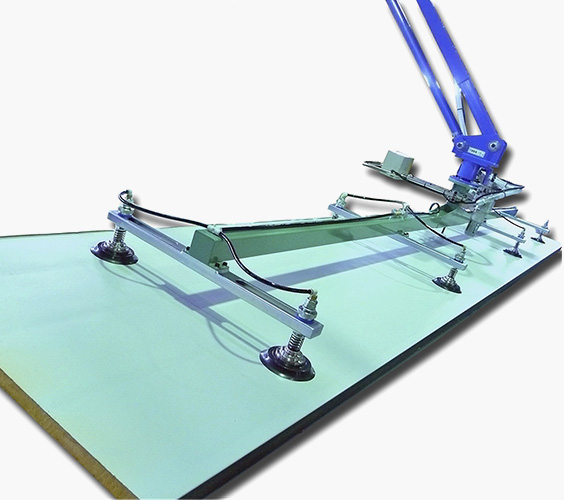

We manufacture glass used in the display of smartphones and other devices.

Can you safely transport a large piece of glass, several meters square, before sending it to the manufacturer?

That's what Balaman does best !

Large, heavy glass panels can be easily and safely moved to equipment or other locations. We also offer a variety of vacuum suction end effectors that allow for rotating the workpiece.

We are a construction materials company that manufactures exterior decorative elements.

A 3-m size on either side of L-shaped decorative laminate material is inspected and sorted into groups after a pass/fail test.

This process required a couple of people. Is there a way to reduce the number of people required for this process?

Let Balaman reduce your labor needs!

Using a Balaman, you can easily and smoothly reduce the number of people required to do the job. You can equip the Balaman with the right end effector to move oddly shaped material and boards either horizontally or vertically using vacuum suction.

We will listen to all your problems and help you find the right specifications and installation method for your Balaman to match your working conditions and solve all your problems.