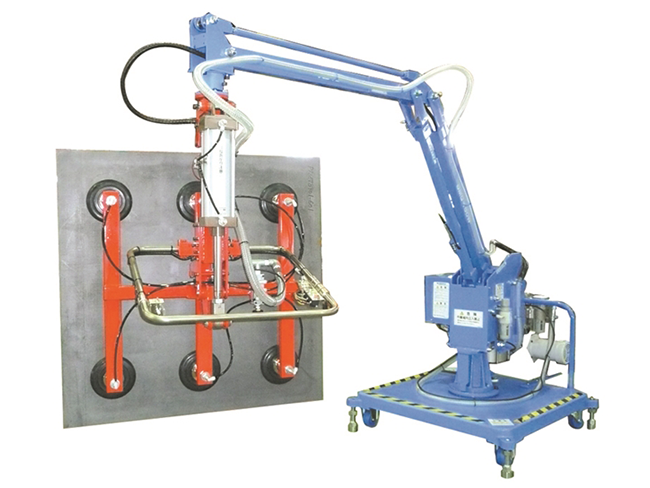

Vacuum Suction Case10

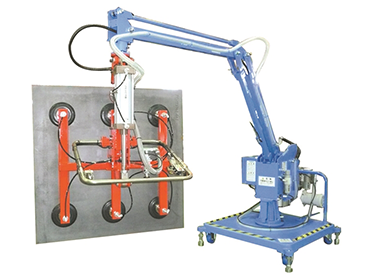

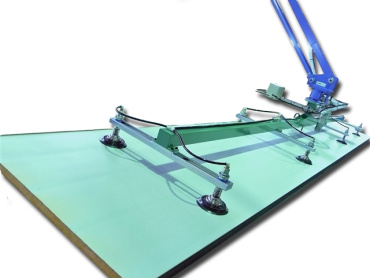

Designed for placing large and cumbersome sheet metals on a laser cutting machine bed. In addition to the vacuum suction mechanism, this end effector is equipped with a workpiece inversing mechanism. Thanks to those mechanisms, you can save labor while improving the working environment.

- Prev

- Next

Specification

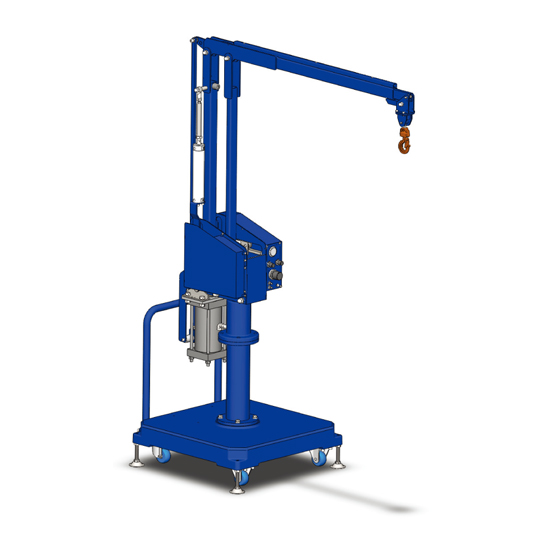

| Type | Pneumatic BALAMAN |

|---|---|

| Model | BMG-150W |

| Main Body options |

|

| Pedestal model | SNG-150W(Floor mobile) ・Vacuum pump mounted |

| Control method | Double control |

| Control options |

|

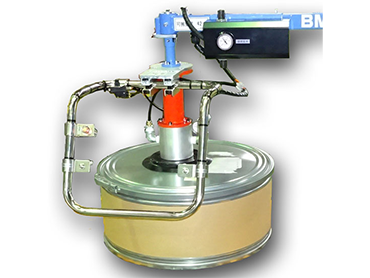

| End Effector |

|

Information

| Workpiece weight | 60kg |

|---|---|

| Max. working radius | R2220mm |

| Operating air pressure | 0.49MPaG |

| Air consumption | 196NL/min(Approx. 10s cycle time) |

| Power supply | AC200V 50/60Hz AC220V-60Hz |

| Rated current | 5.3/5.2A 5.2A |

| Net weight(W/P not included) | 1063kg |

1kg≒2.205lb, 1mm≒0.03937in

BMG-150W

BMG-150W