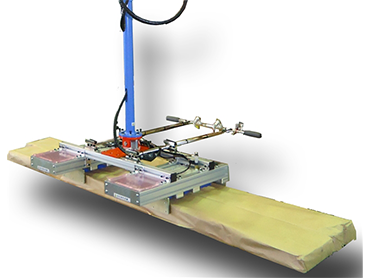

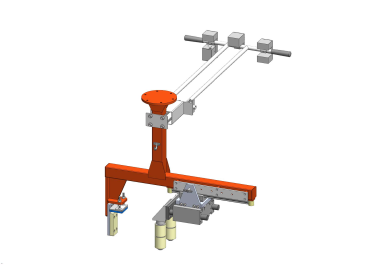

External Clamp Case9

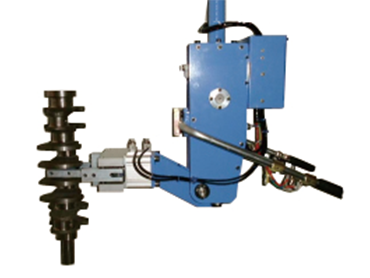

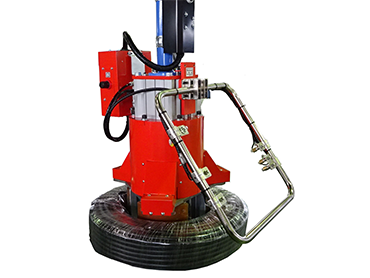

Designed and developed for transporting heavy and cumbersome ingots. Since the end effector is equipped with mechanisms that clamp and rotate the workpiece by 180°, handling is effortless.

- Prev

- Next

Specification

| Type | Pneumatic BALAMAN |

|---|---|

| Model | BMF-375W(4W) |

| Main Body options |

|

| Pedestal model | SNF-375(Floor mobile)(Special) ・Guides for lifter forks |

| Control method | Double control |

| Control options |

|

| End Effector |

|

Information

| Workpiece weight | 223kg |

|---|---|

| Max. working radius | R2260mm |

| Operating air pressure | 0.64MPaG |

| Air consumption | When using clamp end effector: 700NL/min (Approx. 60s cycle time) (Including air motor) When using vacuum end effector 650NL/min (Approx. 20s cycle time) (Including ejector) |

| Net weight(W/P not included) | 1557kg |

| Other | Equipped with Booster Regulator/20L Air Tank |

1kg≒2.205lb, 1mm≒0.03937in

BMF-375W(4W)

BMF-375W(4W)